- Home

- About us

- Product

- Quality

- Infra

- Gallery

-

Investor

- Disclosures Under Regulation 46 of The LODR

- Annualy Report

- Sebi KYC Format

- Quartely Results

- Scrutinizer Reports

- Share Holding Patern

- Unclaimed Dividend

- Stock Prices

- Board Committee

- Board Meeting Notice

- Corporate Governance

- Limited Review Report

- Policy / Info

- Investor Contact

- Code of conduct

- Code Of Practices

- News

- Investor Information

- The Companies Act,2013 Compliance

- Postal Ballot Notice

- Branches

- Contact

Laboratory

SKM egg processing plants entire construction and machinery installation confirms to EU / USDA regulations

- The plant is approved as per the Indian Act “Export of Egg Products Quality Control, Inspection, and Monitoring Rules 1997 Act, based on EU/USDA Guide lines”. The approval number is 05/2/EP/97

- There are two product lines, one for yolk based products and another for egg albumen. The eggs are processed in a modern, fully automated factory using state-of-the-art equipments. The factory is fully air-conditioned and positive pressure is maintained in sterile zones. A fully automatic CIP system has been employed for cleaning the tanks and pipelines.

- The utilities are housed in a separate building to eliminate the possibility of any contaminants in the processing area. The effluent generated are treated and put to use in accordance with the environmental norms to make processing eco-friendly.

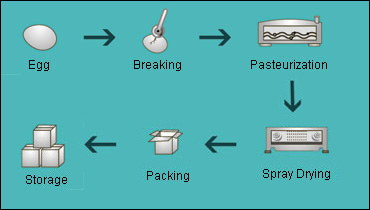

Process : SKM uses only microbiologically tested eggs for breaking and can break 1.8 million eggs a day to produce 6500 tons of finished products in a year. Customer collaborative new recipes are formulated, either co-dried or dry blend products.SKM follows the cGMP, Sanitation Standard Operating Procedure (SSOP), general principles and guidelines as per Codex Alimentarius, which forms a part of the HACCP.The entire activity is monitored and controlled by newly developed TRACKKER system, to manage food safety and traceability.

Zoning :SKM has an effective program for the prevention of microbial cross contamination within the factory premises. Critical areas of the process are categorized into red, white and neutral zones. The consumables including the cleaning tools are different for each zone.

Hygiene :Cleanliness is of paramount importance within the processing area. Regular cleaning arrangement disinfects the premises and the equipments. Workers enter the processing hall only after having shower bath, wearing disinfected clothes, head gear and shoes. Regular swabs are taken on the process equipments, floors, walls and the personnel. Periodical monitoring of the air-contamination is done by Gravitometric plate exposure method.